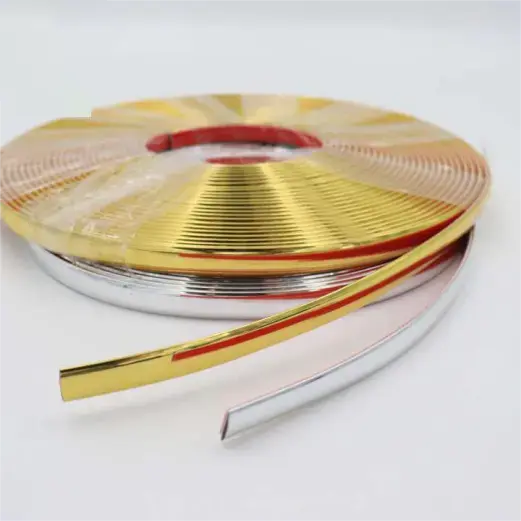

Abs Edge Banding Strip for Furniture

Send Inquiry

|

material |

edge banding profile |

|

Thickness |

<0.4mm |

|

Width |

9-50mm |

|

feature |

Strong, water resistant, Self Adhesive |

|

place of origin |

Shandong, China |

|

model number |

PE-AD.104 |

|

Material |

PVC |

|

Color |

Gold,Silver |

|

Type |

Edging Trim |

|

Advantage |

Strong Adhesive |

|

Application |

Furniture Edge Banding |

|

Packing |

Carton |

|

Feature |

Eco-friendly |

|

Supply ability |

19000meters/day |

|

Usage |

Kitchen Cabinet Edging |

Packaging and delivery

|

Selling Units |

Single item |

Single package size |

40X40X12 cm |

|

Single gross weight |

16.000 KG |

|

|

◼️ Material Advantages

|

Property |

ABS Edge Banding |

PVC Edge Banding (Comparison) |

|

Impact Strength |

40 kJ/m² (ISO 179) |

15–25 kJ/m² |

|

Thermal Stability |

-40°C to 90°C |

-10°C to 70°C |

|

Chemical Resistance |

Resists oils, acids, cleaners |

Limited solvent resistance |

|

Eco-Profile |

Halogen-free & recyclable |

Contains chlorine (hard to recycle) |

|

Surface Finish |

Glossy/matte/textured options |

Prone to scratching |

◼️ Technical Specifications

|

Parameter |

Specification |

|

Thickness |

0.4–2.0 mm (16–80 mil) |

|

Width |

15–60 mm (standard), custom ≤150 mm |

|

Roll Length |

200–800 meters (core ID: 76 mm) |

|

Peel Strength |

≥3.8 N/mm (EN 1464) |

|

Bending Radius |

≥R3 mm (cold bending) |

|

Fire Rating |

Class B-s1,d0 (EN 13501-1) |

◼️ Key Features & Benefits

· Laser-Ready Finish: Smooth surface for digital printing (RAL colors, wood grains, metallics)

· Pre-glued Option: Thermoplastic adhesive backing (EVA/PUR) for instant heat application

· Weather Resistance: UV-stabilized grades for indoor/outdoor use (ΔE<2 after 3,000 hrs QUV)

· Easy Processing:

· Hot-air welding compatible (no delamination)

· CNC-trimmable with carbide blades

· Hygienic Surface: Non-porous, microbial growth resistant (ISO 22196)

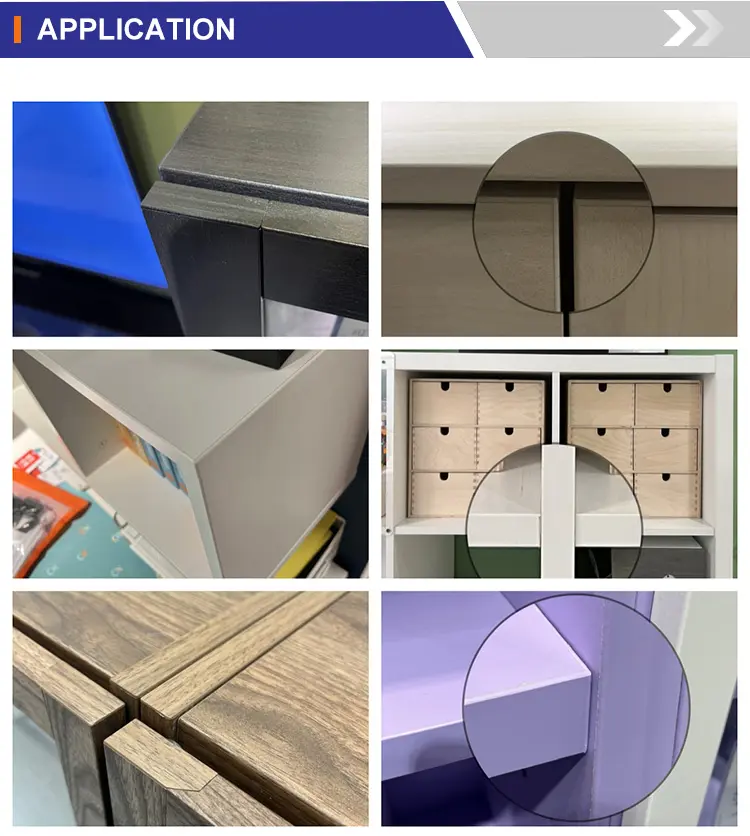

◼️ Applications

Furniture Manufacturing:

· Cabinet edges, tabletops, and drawer fronts

· Office partition panels and display shelves

Architectural Elements:

· Stair nosing, door frames, and window sills

· Laboratory countertop cap strips

Specialty Uses:

· Automotive interior trim

· Exhibit booth construction

◼️ Installation Guidelines

00001. Surface Prep: Clean substrate (dust-free, moisture <8%)

00002. Heating:

· Hot-air nozzle: 180–220°C

· Contact roller pressure: 0.3–0.5 MPa

00003. Trimming: Single/double-flute trimming cutters

00004. Finishing: Buffing wheel for high-gloss edges

Critical Tip: Store rolls vertically at 15–25°C/40–60% RH to prevent curvature memory.

◼️ Sustainability & Compliance

· Certifications: REACH, RoHS, CARB Phase II (NAF)

· Recycling: >98% pure ABS regrind reusable in injection molding

· Indoor Air Quality: Zero formaldehyde (≤0.005 ppm per EN 717-1)

· Food Safety: FDA 21 CFR & EU 10/2011 compliant

Product descriptions from the supplier

|

Products name |

Self- Adhesive flexible Molding Trim |

|

Width |

11.5mm |

|

Thickness |

3.2mm |

|

Material |

PVC |

|

MOQ |

1000Meters |

|

Mail packing |

N |

Company Profile

Future Colors (Shandong) Material Technology Co., Ltd. focuses on the research and development, production, and sales of customized high-quality film coatings. The products include plastic absorbing PVC film, coated PVC film, PETG film, and PP film. Currently, the company's main products have more than 2000 designs and colors, and the soul of enterprise development cannot be separated from innovation. After years of development, Future Color is located in Jinan, Linyi, Shijiazhuang, Zhengzhou, Hangzhou, Chengdu, Guiyang, Shenyang, Xi'an and other places have established direct sales companies and warehousing centers. Product quality is the lifeblood of an enterprise's survival and development.Future Color has been deeply cultivated and cultivated in various decorative film industries for many years. Product quality has always been our core competitiveness that we value most. We have a complete set of inspection and testing process systems, complete inspection and testing equipment, and implement testing data that is higher than industry standards.We will randomly select samples for each batch of film produced, Cutting, sampling, and testing according to the size required by the testing instrument, using a professional knife to cut the film, testing the adhesion of the surface treatment layer, hardness testing, using a pencil hardness tester, conducting surface hardness testing, wear resistance testing, surface hardness of the film, weather resistance testing, UV testing,and carefully preparing each batch of film are our lifelong pursuit.

Our Service Team

Quality, affordability and cooperation with the best customization are our strengths.We produce with high quality production and regular diverse designs. We strictly control the quality of our products and cooperate with the trust and support of our customers in many countries around the world at competitive prices. We always focus on customers and provide high quality and efficient service.

Certificates

FAQ

Q: Are you a factory or trading company?

A: We are professional manufacturer, and we have more than 10 years for exporting and wood product's experiences.

Q: Where is your company located?

A: Office in Shandong,factory in Jinan City.

Q: Do you have MOQ request?

A: Our MOQ 1000 meters.

Q: What is your delivery time?

A: The delivery time is 3-15days after received your deposit.

Q: What is the delivery port?

A: QingDao Port.

Q: Do the samples are available?

A: Yes, the sample is free and express charge on buyer account.

And after the order is confirmed, this charge could be returned from the order.

Q: May I visit your factory for inspection before placing the order.

A: You are warmly welcome to visit our factory anytime. Please let us know your

schedule in advance so that we can book hotel and arrange pickup for you.