Decorative PVC Films for Vacuum Forming

Send Inquiry

Key attributes

|

Type |

Decorative Film |

|

Design Style |

Modern |

|

Thickness |

0.35mm |

|

Length |

Customized |

|

Surface Treatment |

Embossed, Frosted |

|

Brand Name |

Future Colors |

|

Material |

PVC Material |

|

Sample |

Free! |

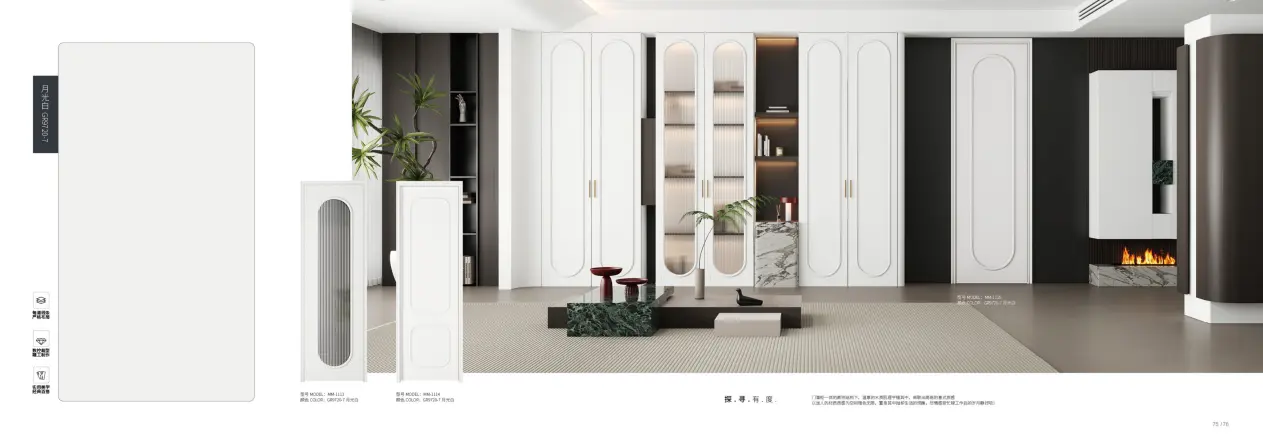

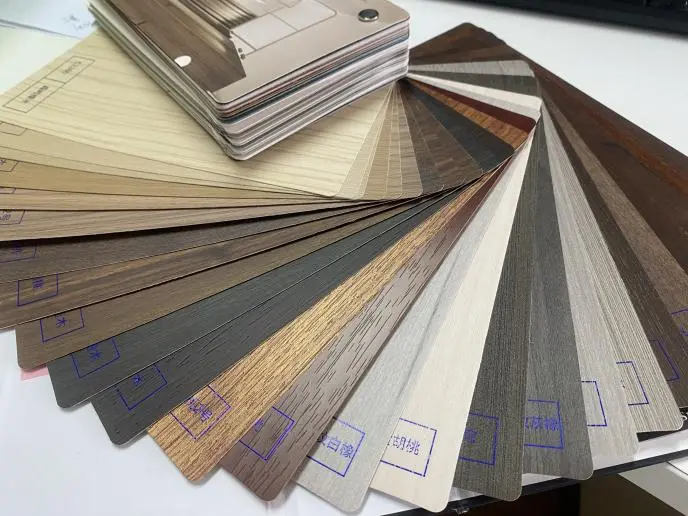

In terms of effect, Decorative PVC Films for Vacuum Forming are mainly divided into the following categories:

·Wood Grain Series: As a mainstream category, Decorative PVC Films for Vacuum Forming account for over 60%. They are subdivided into "natural wood grains " and "technical wood grains", and are suitable for scenarios such as furniture, wooden doors, and flooring.

·Stone Grain Series: Stone grain Decorative PVC Films for Vacuum Forming replicates the textures of marble, granite, and microcement. They are mostly used for kitchen countertops, bathroom vanities, and wall decoration, replacing natural stone to reduce weight and cost.

·Metal Series: Metal Decorative PVC Films for Vacuum Forming achieve effects such as brushed gold, matte silver, and champagne gold through vacuum coating or printing. They are applied to home appliance panels (e.g., casings of refrigerators and washing machines) and automotive interiors.

·Solid Color/Texture Series: Solid colors (Morandi colors, high-end gray) Decorative PVC Films for Vacuum Forming are matched with textures like "skin-feel, suede, and frosted". This series is suitable for minimalist-style furniture, children's room decoration, and other scenarios.

FAQ

1. Will Decorative PVC Films for Vacuum Forming peel off? Under normal circumstances, decorative films will not peel off. However, they may peel off if the substrate is not properly prepared (e.g., there are oil stains or dust on the surface) or if the blister process parameters are incorrect (e.g., excessively low temperature, insufficient pressure).High-quality films can have a service life of 5-10 years when installed correctly.

2.Can Decorative PVC Films for Vacuum Forming be replaced a second time? Yes, but note the following: PVC films are easy to soften when heated and can be peeled off for reapplication; PET films have strong adhesion, and peeling may damage the substrate surface, so professional operation is recommended.

3.What is the difference between Decorative PVC Films for Vacuum Forming and "wrapping films"? The main difference lies in the process: Blister films adopt the method of "heating + negative pressure to adhere to irregularly shaped substrates" and are suitable for curved surfaces and grooves; Wrapping films, on the other hand, "adhere to flat or simple curved substrates via rollers at room temperature". Although wrapping films have weaker formability than blister films, their cost is lower.

4.Can Decorative PVC Films for Vacuum Forming be used in outdoor scenarios? It is necessary to select special films with "UV resistance + water resistance" (e.g., outdoor-specific PET films with added UV stabilizers). Ordinary films will fade and age when exposed to sunlight for a long time, with a service life of only 1-2 years.

Finally, Decorative PVC Films for Vacuum Forming is a high-efficiency decorative material that "replaces wood and stone with plastic". Its development has always centered on "performance upgrading + environmental optimization + scenario adaptation". In the future, it will replace traditional materials in more fields and become one of the "core consumables" in the decoration industry.