What is the vacuum forming process of blister film?

2025-10-11

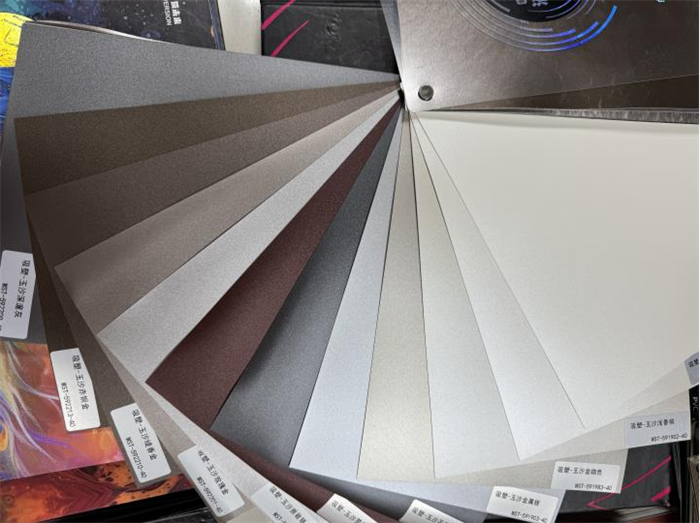

Furniture decorative films can simulate a variety of textures and colors such as wood grain, metal, and solid colors, meeting the design needs of furniture in different styles.

Whether one pursues the natural and warm texture of solid wood, prefers the simple and modern solid-color style, or intends to create avant-garde and personalized furniture with a metallic texture, blister film can present it accurately, endowing furniture with a more layered and design-oriented appearance.

As an important category of furniture decorative films, blister film is not only widely used in the production of furniture components such as cabinet door panels and bathroom door panels, but also can be applied to the surface decoration of customized furniture. It creates a unified and harmonious decorative atmosphere for home spaces, and at the same time, its cost advantage enables high-quality furniture with excellent cost performance to enter more families.

Blister film, as an important and highly practical category within the family of furniture decorative films, has always held a significant position in the field of interior decoration due to its combination of practicality and aesthetics, providing an excellent solution for the surface treatment of various types of furniture.

As a widely used category of furniture decorative films, blister film, with polyvinyl chloride (PVC) as its core material, has an extremely strong impact resistance, effectively protecting the surface of furniture from possible collisions and abrasions during daily use. Meanwhile, its excellent corrosion resistance enables it to easily cope with humid environments and slight acid and alkali erosion. Whether it is the oil and water vapor in kitchen cabinets or the moist air that bath cabinets come into contact with, vacuum-formed film can maintain its surface integrity and extend the service life of furniture. In addition, blister film also has good air tightness, which can closely adhere to the surface of the board, reducing the infiltration of external dust and impurities, and further protecting the furniture base material.

In terms of process application, the blister film can be firmly adhered to the surface of common furniture boards such as density board and plywood through a professional vacuum laminating machine, achieving seamless covering.So,what is the vacuum forming process of blister film?

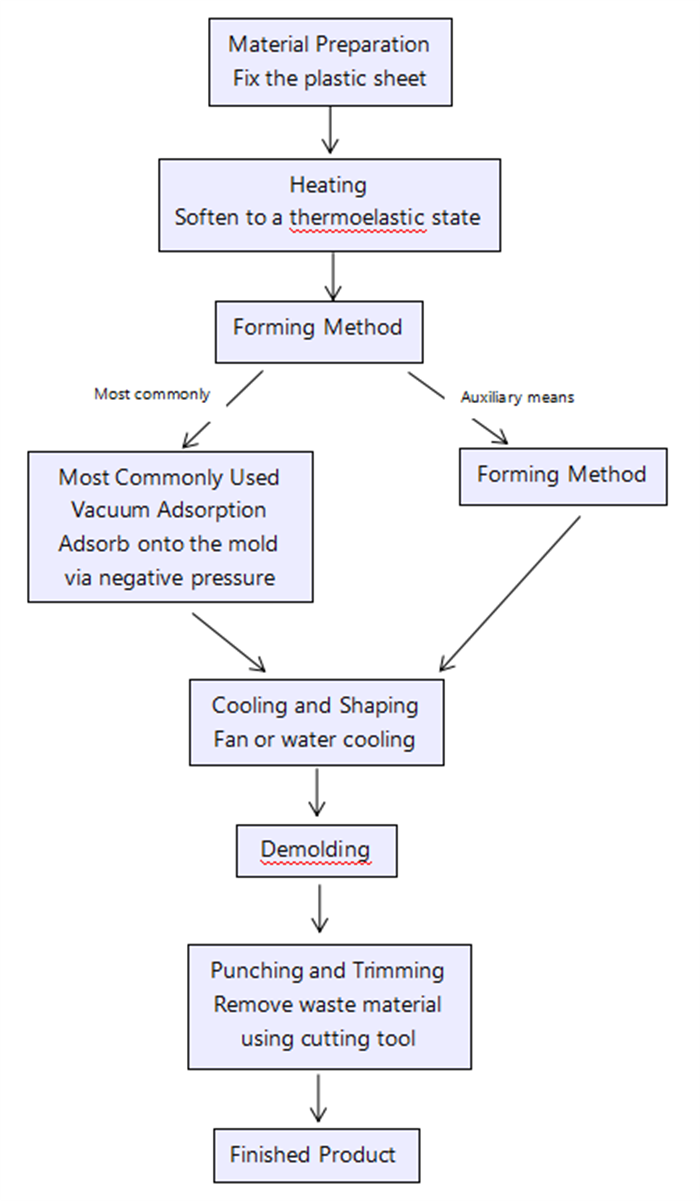

Core Principle: Heat and soften the plastic sheet, then use vacuum to adsorb it onto the mold surface, and it will take shape after cooling.

Step 1: Material Preparation

·According to product requirements,such as thickness, color, environmental standards, etc., select and cut appropriate plastic sheets (such as PVC, PET, PP, PS, etc.).

·Fix the sheets on the feeding rack or frame of the blister machine.

Step 2: Heating

·The fixed plastic sheet is uniformly heated by the heating furnace of the blister machine (usually equipped with far-infrared heating tubes).

·Heat the sheet until it softens and reaches a thermoelastic state, preparing for the next molding step. The temperature and heating time need to be precisely controlled.Step 3: Forming

·This is the most critical step.

·The softened sheet is quickly moved directly above the mold.

·The lower mold table rises to press the sheet tightly against the mold box, creating a sealed state.

·The vacuum pump is activated, and the air between the sheet and the mold is sucked out through the tiny air holes on the mold. Under the action of atmospheric pressure, the softened sheet is tightly "sucked" onto the mold surface, forming a shape consistent with the mold.

·(In some cases, compressed air is also used to blow from top to bottom, or an "upper mold" is pressed down to assist in forming, ensuring perfect details.)

Step 4: Cooling & Demolding

·After forming, the vacuum state is maintained, and the product adsorbed on the mold is cooled by means of fans, water cooling, or other methods to set its shape.

·Once cooled, the vacuum is released, the mold descends, and the formed product can be separated from the mold.Step 5: Trimming

·After forming and cooling, the products are removed from the machine together with the surrounding waste material—typically, one or more products are still attached to a large sheet.

·They need to be placed into a punch press or cutting machine, where a pre-made die is used to punch out the waste material outside the product outline, resulting in individual finished products.

·For some specific products, additional post-processing such as manual trimming may also be required.

Blister film is a new type of environmentally friendly decorative material, mainly used in the furniture, cabinet, and decorative board industries. It can not only be applied for surface laminating but also undergo vacuum blister forming. It is very efficient to process, features excellent shaping performance, good water resistance, and outstanding corrosion resistance, and is relatively easy to clean.