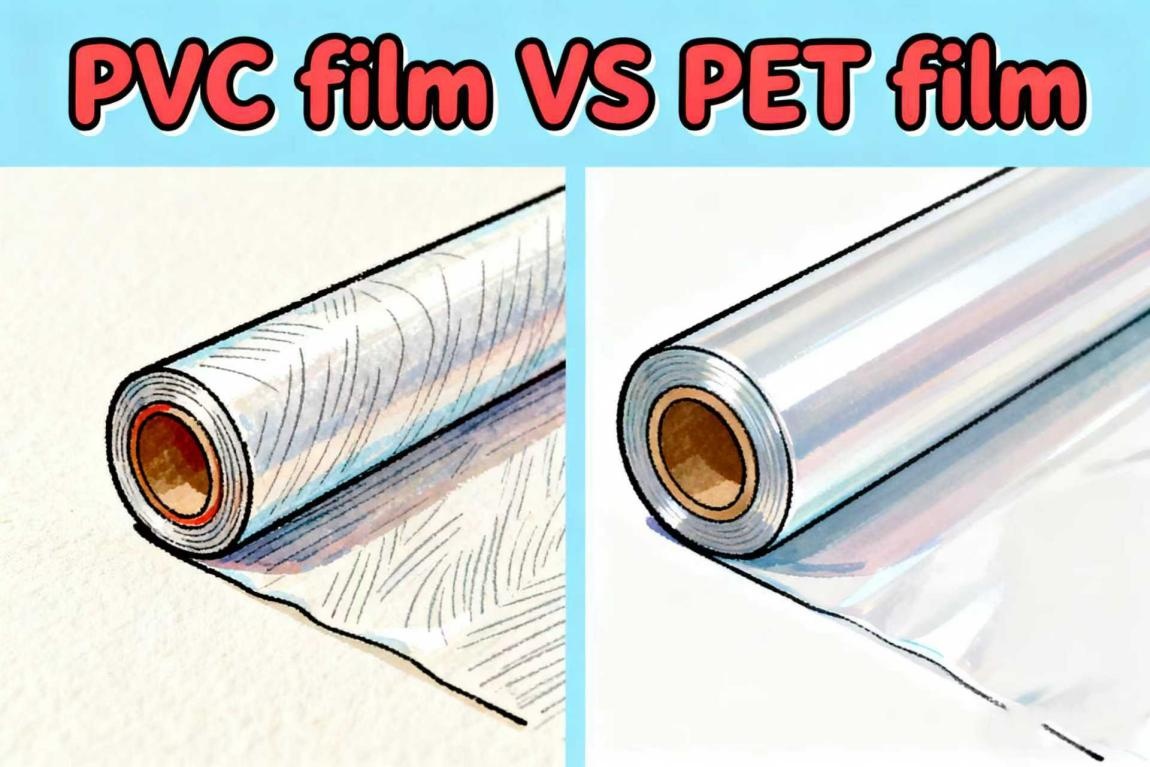

What is the difference between PET and PVC film?

2025-10-13

PVC (Polyvinyl Chloride) decorative film and PET (Polyethylene Terephthalate) decorative film are two mainstream surface decorative materials currently on the market. Each has its own characteristics, and their application fields also have different focuses. The following is a detailed comparative analysis of them from multiple dimensions.

Ⅰ. What are the main differences between PVC and PET decorative films?

PVC Film: As a mainstream product in the market, it is known for its high cost-effectiveness and wide applicability. Its advantages include good flexibility, scratch resistance, and a rich variety of patterns/colors; its shortcomings lie in relatively average environmental friendliness (contains chlorine), high-temperature resistance, and anti-yellowing performance.

PET Film: A new environmentally friendly option positioned in the mid-to-high-end segment, with excellent comprehensive performance. Its prominent strengths are outstanding visual texture (high gloss/skin-friendly touch), food-grade safety, and excellent anti-yellowing and chemical resistance; its main drawbacks are relatively high price and slightly inferior flexibility.

Ⅱ. Specifically, in what aspects do PVC and PET decorative films differ?

|

Characteristic Dimension |

PVC Decorative Film |

PET Decorative Film |

|

Substrate & Composition |

Polyvinyl chloride, may contain plasticizers (e.g., DOP) and stabilizers. |

Polyethylene terephthalate, chlorine-free, no plasticizers required. |

|

Environmental Friendliness |

Relatively low. Contains chlorine and produces toxic gases when burned. Some low-end products may contain harmful substances such as heavy metals. VOC (Volatile Organic Compounds) emissions are relatively high. |

Very high. Food-grade contact material, non-toxic and odorless, and recyclable. Combustion products are mainly carbon dioxide and water, which are safer. |

|

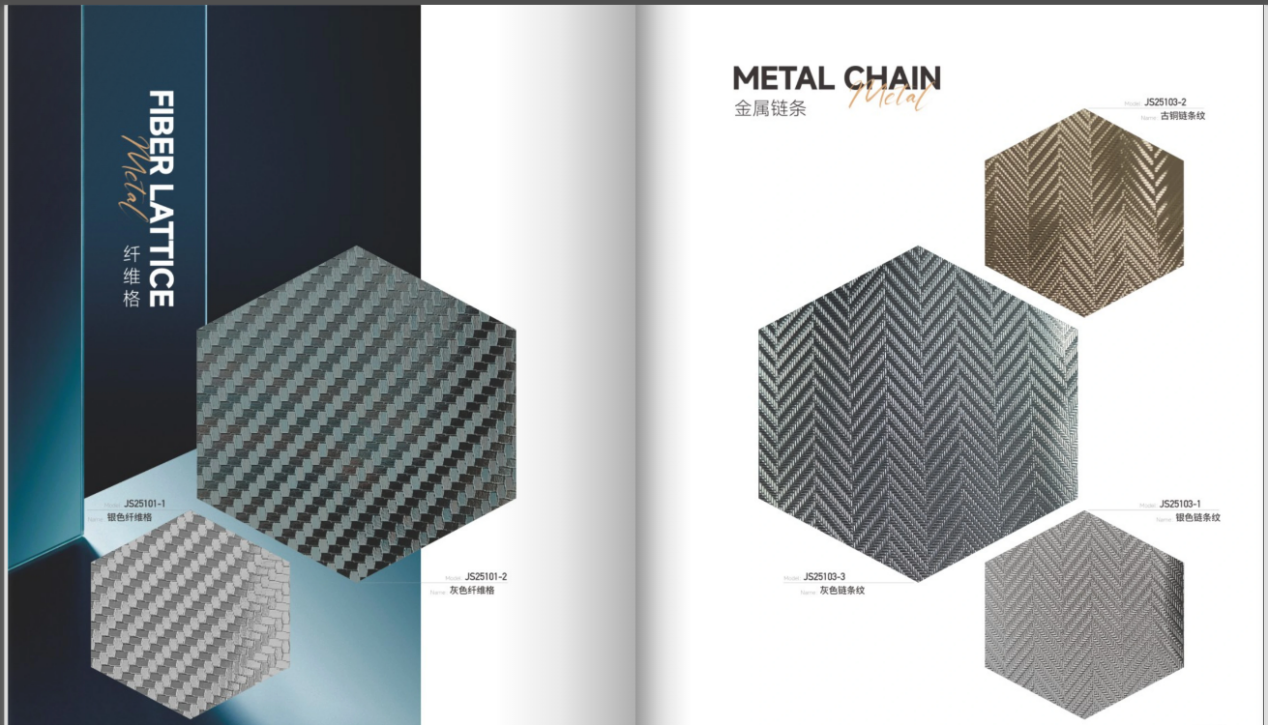

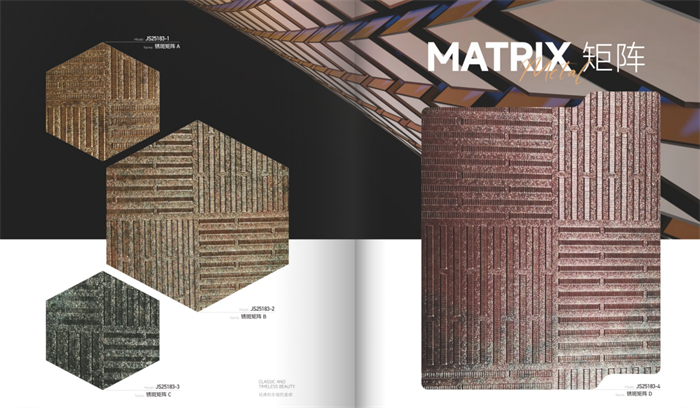

Surface Texture & Appearance |

Offers an extremely rich range of patterns, capable of simulating wood grain, fabric texture, stone grain, etc. It has a wide range of gloss levels, but its visual sense of premium quality is usually not as good as that of PET. |

Excellent texture. High-gloss surfaces are as transparent as mirrors; skin-friendly surfaces have a delicate and smooth touch and are anti-fingerprint. The appearance is more high-end and modern. |

|

Physical Properties |

Excellent flexibility, with strong capabilities for deep embossing and wrapping complex edges/corners. Good scratch resistance. |

High hardness and strong rigidity. Poor flexibility, not suitable for overly complex wrapping as it tends to rebound. Excellent scratch resistance. |

|

Chemical Resistance |

Average; not resistant to strong acids, strong alkalis, and some solvents. |

Excellent; can resist the corrosion of most acids, alkalis, oils, alcohols, and cleaning agents. |

|

Weather Resistance & Anti-Yellowing |

Average. Easily ages, yellows, and becomes brittle when exposed to ultraviolet rays (e.g., sunlight) for a long time. |

Excellent. Strong UV resistance, not prone to yellowing during long-term use, and color remains stable. |

|

High-Temperature Resistance |

Poor; low softening point (approximately 70-80℃), and easily deforms when close to heat sources (e.g., stoves). |

Good; can withstand higher temperatures (up to over 100℃) and has better thermal stability. |

|

Price |

Economical and affordable. Mature production process leads to low cost and high cost-effectiveness. |

Relatively high. Both raw material and production costs are higher than those of PVC, positioning it in the mid-to-high-end market. |

|

Main Application Fields |

Widely used in cost-sensitive scenarios such as cabinets, wardrobes, office furniture, interior doors, and display cabinets. |

Mainly used in high-end cabinets (especially cabinet doors), home appliance panels (e.g., refrigerators, washing machines), electronic products, medical clean panels, and other fields with high requirements for environmental friendliness and appearance. |

Ⅲ. What Are the Core Differences Between PVC and PET Decorative Films?

1. Environmental Friendliness and Health: The Most Critical Difference This is the greatest advantage of PET film.

- PVC: Due to the chlorine in its composition and the potential use of phthalate plasticizers, it has always been the focus of environmental controversies. In markets such as Europe, there are strict restrictions on the use of PVC. In enclosed indoor spaces, low-quality PVC film may release trace amounts of harmful substances for a long time.

-PET: Its raw material is the same as that used to make mineral water bottles, meeting food contact-grade standards. It is safer and more eco-friendly during both production and use, aligning with modern consumers' pursuit of healthy home environments.

1. Appearance and Touch: Upgrades in Vision and Experience

- PVC: Although it can also achieve various effects, it is slightly inferior in creating a "sense of premium quality". For example, the transparency and mirror effect of high-gloss PVC are usually not as good as those of PET.

- PET: Skin-friendly PET, in particular, has been extremely popular in recent years. It provides a delicate touch similar to that of a baby's skin or velvet, and at the same time, it is not easy to leave fingerprints, which greatly improves the product's grade and user experience.

2. Processing and Application: Flexibility Determines the Process

-PVC: Its excellent ductility and flexibility make it very suitable for the wrap-molding process, which can perfectly cover all edges and corners of the board as well as complex shapes.

-PET: Its relatively high rigidity and hardness make it more suitable for flat lamination or edge banding processes, and it is often used to make large-sized flat cabinet doors. If it is forced to be used for complex wrapping, problems such as unstable edge wrapping, rebound, and glue failure are likely to occur.

Ⅳ. PVC/PET Decorative Films,how to Choose?

Choose PVC film if:

You have a limited budget and pursue high cost-effectiveness.

You need to cover complex shapes and irregular edges/corners.

The application environment is non-high-temperature and not exposed to direct sunlight for a long time.

It is used in ordinary commercial or residential spaces where environmental protection requirements are not extremely strict.

Choose PET film if:

You pursue a high-end, modern home style and value skin-friendly or high-gloss texture.

You prioritize environmental protection and health (e.g., children's rooms, families sensitive to odors).

It is used for kitchen cabinets (oil-resistant, high-temperature-resistant) or bathroom vanities (resistant to moisture and chemicals).

The product is used for home appliance panels or scenarios requiring excellent anti-yellowing performance.

In conclusion, PVC and PET decorative films are two generations of products catering to different market demands. PVC is a mature, economical, and versatile solution, while PET is an upgraded option that is more environmentally friendly, more aesthetically pleasing, and offers superior performance.

As consumers' requirements for quality and health continue to rise, the market share of PET films is growing rapidly. However, relying on its excellent processing adaptability and cost advantages, PVC films will still occupy an important position in the foreseeable future. When making a choice, be sure to decide based on your specific project needs, budget, and the level of importance you attach to environmental protection.