Polyester Mylar PET Film for Insulation and Versatile

Send Inquiry

|

Hardness |

Soft |

|

Transparency

|

Opaque |

|

Industrial Use |

Insulation |

|

Type |

Stretch Film |

|

Material |

PET |

|

Feature |

Moisture Proof |

|

Processing Type |

Multiple Extrusion |

|

Width |

Customized Size |

|

Surface |

Plane |

|

Product name |

White opaque PET Film |

|

Colors |

White |

|

Packing |

Wodden Pallet |

|

MOQ |

3000kgs |

|

OEM |

OEM Service Accepted |

|

Sample |

A4 Size Samples |

|

Application |

Insulation |

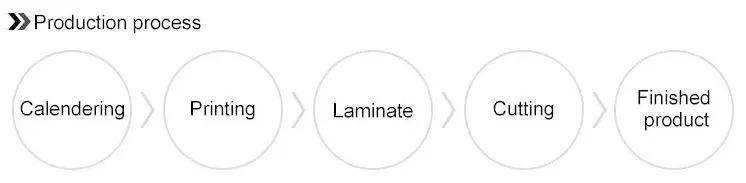

◾ Versatile Applications

00001. Electrical Insulation

· Motor/generator slot liners, transformer coil wraps, and switch baseplates

· Capacitor dielectric layers and cable wrapping tapes

00002. Industrial Materials

· Flexible composite substrates for printed circuits

· Protective layers for fiberglass sheets during molding

00003. Specialized Uses

· Jelly-filled telephone cable insulation and metallized film backings

· High-barrier packaging for sensitive components

◾ Manufacturing Standards

· Complies with UL/certified insulation class standards (e.g., Class F/H)

· Free of phthalates and heavy metals, meeting RoHS directives

Critical Note: Milky white variants (e.g., Type 6021) enhance light diffusion in backlit displays, while transparent grades optimize optical clarity

Product Description

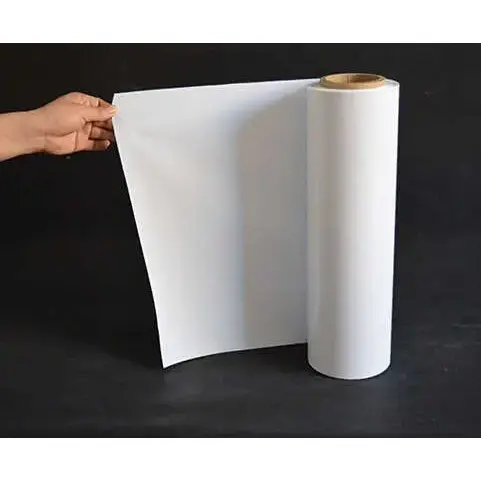

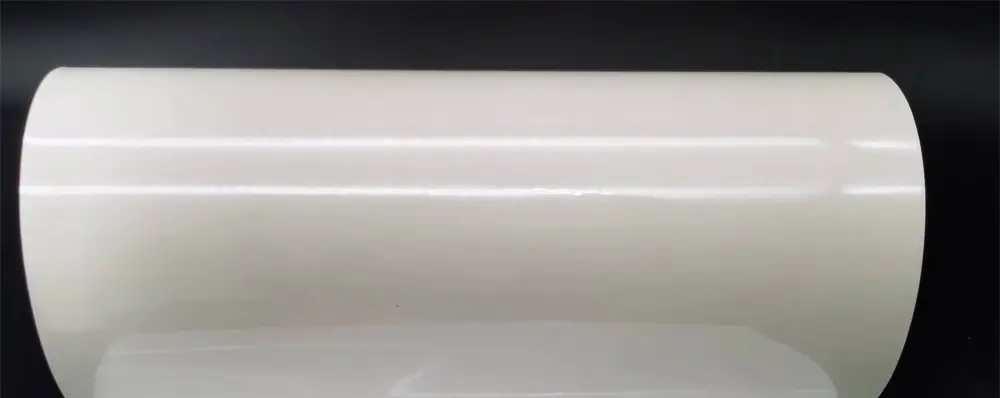

50micron Matte Opaque White PET Polyester Mylar Film is Porcelain White, matte white, and glossy White. We also produce Narrow width White opaque PET film , like:2'', 2.5'', 3'', 3.5'', 4'' ect it also named opaque white mylar tape. It can be use for cable insulation . It also mainly used in Label, High-grade flexible packaging, Building materials , Decorating materials etc.It is Pure white, opaque almost. It have excellent mechanical properties. Features: Shading light,white,outstanding mechanical strength,excellent resistance to heat.

Application: PET white film is mainly suitable for: printing, electronics, packaging,insulation film, flexible printed circuit, the display screen saver pet, coating, coating silicon, electrical insulation gasket,cable, instrument panel, capacitance, furniture supporting film, back light diffusion, soft lines, printing, nameplate, membrane switch, digital color makeup, CARDS, stickers printing, micro film, slides, and decoration, glance back light and shade, liquid crystal displays, LCD, LED, DVD screen protection, light box advertising, chimney, signs, etc.

|

Items |

Test methods |

Units |

Typical value |

|

|

Thickness |

GB/T6672 |

μm |

50 |

|

|

Tensile strength |

MD |

GB/T13022 |

Mpa |

170 |

|

TD |

180 |

|||

|

Elogation at break |

MD |

GB/T13022 |

% |

80 |

|

TD |

80 |

|||

|

Heat shrinkage |

MD |

GB/T16958 |

% |

1.5 |

|

TD |

-0.5 |

|||

|

Friction of coefficient |

GB/T10006 |

- |

0.3 |

|

|

Haze |

GB/T2410 |

% |

96 |

|

|

Gloss |

GB/T8807 |

% |

60 |

|

|

Wetting tension |

GB/T14216 |

mN/m |

44 |

|

Company Profile

Future Colors (Shandong) Material Technology Co., Ltd. focuses on the research and development, production, and sales of customized high-quality film coatings. The products include plastic absorbing PVC film, coated PVC film, PETG film, and PP film. Currently, the company's main products have more than 2000 designs and colors, and the soul of enterprise development cannot be separated from innovation. After years of development, Future Color is located in Jinan, Linyi, Shijiazhuang, Zhengzhou, Hangzhou, Chengdu, Guiyang, Shenyang, Xi'an and other places have established direct sales companies and warehousing centers. Product quality is the lifeblood of an enterprise's survival and development.Future Color has been deeply cultivated and cultivated in various decorative film industries for many years. Product quality has always been our core competitiveness that we value most. We have a complete set of inspection and testing process systems, complete inspection and testing equipment, and implement testing data that is higher than industry standards.We will randomly select samples for each batch of film produced, Cutting, sampling, and testing according to the size required by the testing instrument, using a professional knife to cut the film, testing the adhesion of the surface treatment layer, hardness testing, using a pencil hardness tester, conducting surface hardness testing, wear resistance testing, surface hardness of the film, weather resistance testing, UV testing,and carefully preparing each batch of film are our lifelong pursuit.

Our Service Team

Quality, affordability and cooperation with the best customization are our strengths.We produce with high quality production and regular diverse designs. We strictly control the quality of our products and cooperate with the trust and support of our customers in many countries around the world at competitive prices. We always focus on customers and provide high quality and efficient service.

Packaging

Certificates

FAQ

Q: Are you a factory or trading company?

A: We are professional manufacturer, and we have more than 10 years for exporting and wood product's experiences.

Q: Where is your company located?

A: Office in Shandong,factory in Jinan City.

Q: Do you have MOQ request?

A: Our MOQ 3000kgs.

Q: What is your delivery time?

A: The delivery time is 3-15days after received your deposit.

Q: What is the delivery port?

A: QingDao Port.

Q: Do the samples are available?

A: Yes, the sample is free and express charge on buyer account.

And after the order is confirmed, this charge could be returned from the order.

Q: May I visit your factory for inspection before placing the order.

A: You are warmly welcome to visit our factory anytime. Please let us know your

schedule in advance so that we can book hotel and arrange pickup for you.